R-Tank Saves Space at Maine Medical Center

A small-footprint subsurface stormwater storage system freed up space in a busy parking lot and saved the contractor precious time and money.

Download Case Study

Challenge

A medical center in Maine was struggling to find a seamless solution for managing stormwater. Due to limited space in their busy parking lot, conventional approaches fell short. That is why they contacted Ferguson Waterworks. Not only to provide a unique layout alternative but also to avoid costly delays.

The original stormwater design was a “pipe and stone” storage system. However, that approach requires a large footprint. Furthermore, concerns arose that the pipe system could be damaged during the construction of the building. For example, heavy delivery vehicles and cranes could potentially crush the pipe.

Solution

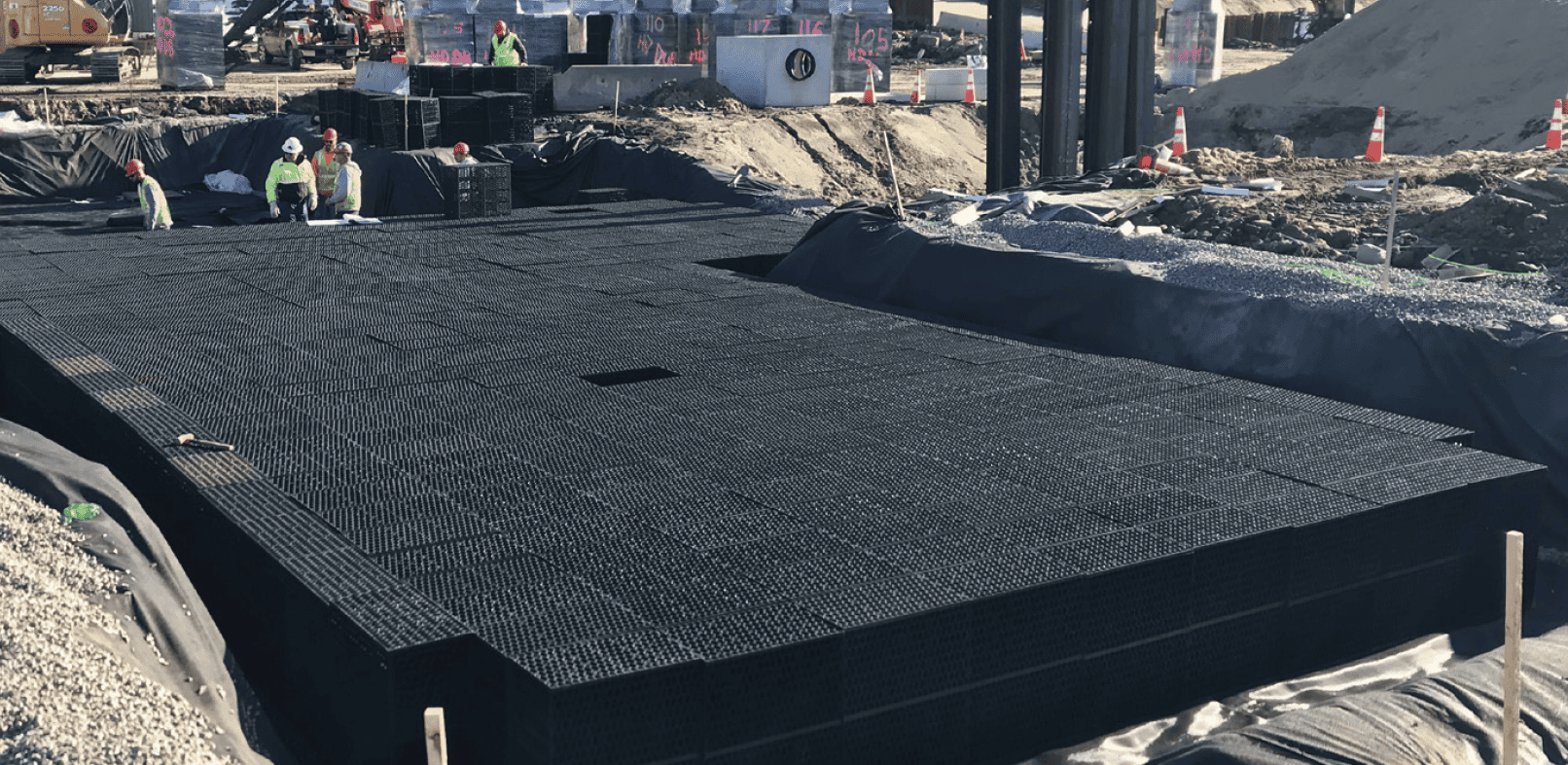

Ferguson Waterworks was engaged by the general contractor and the engineer of record. We were tasked to develop an efficient and customized R-Tank layout design. To begin, we designed the R-Tank using our intuitive R-Tank Design Tool. The goal of the design was to reduce the footprint of the stormwater storage system, meanwhile maintaining the equivalent amount of storage. Due to the smaller footprint of the subsurface stormwater storage, there was sufficient space for the crane and other construction vehicles to operate outside of the system’s footprint.

Product Advantages

- 95% void space provided the most efficient storage while minimizing the system’s footprint

- Module Strength—easily supports traffic loads

- Versatile system layout

- Pre-assembled modules for fast installation

- Inspection/maintenance row for system accessibility, inspection and maintenance

Background

Maine Medical Center’s main campus, the largest medical facility in the state, is in the heart of Portland. It serves Maine and northern New England. The main campus is located in Maine’s most densely populated neighborhood and provides medical resources to everyone in the community. This multi-campus teaching hospital is one of the top hospitals in the U.S. Furthermore, it is home to the Barbara Bush Children’s Hospital (also considered one of the top children’s hospitals in the country).

Project Success

The hospital has experienced significant growth over the years. Finding space in Portland’s urban environment and the fast-growing housing market has proven challenging for the hospital’s expansion. Furthermore, it was extremely problematic to find a large enough space for staff and visitor parking. The hospital acquired nearby property to redevelop and construct a large-scale parking lot for staff and visitors. The parking lot required a subsurface stormwater detention system to maximize on-site space and, therefore, efficiently use the highly valuable real estate.

Method

The design engineer utilized the R-TankHD Subsurface Detention System to create a subsurface layout. As a result, we optimized the construction process because the layout provided enough space for construction vehicle traffic. Alternatively, other layouts forced construction vehicles to take longer detours, ultimately hindering the progress. The R-TankHD Subsurface Detention System is a simple way to accommodate site-specific constraints and a viable solution for stormwater design challenges. Even in the field, when unexpected conflicts arise, the R-tank system layout is easy to adapt while adhering to the required storage volumes. In some instances where conflicting utilities posed a challenge, the R-Tank modules were relocated (not removed) to provide the same storage volume for the entire system.

WHY FERGUSON WATERWORKS?

Ferguson Waterworks engineering team quickly provided an R-Tank system design. As a result, the project remained on schedule. Furthermore, we supported the team throughout the construction process, assisting the contractor with answers to installation questions. However, Ferguson’s detailed knowledge goes beyond materials and products. We understand the challenges and costs associated with projects that go over the scheduled time. That awareness makes us an excellent partner, dedicated to providing high-quality solutions that help your project stay on schedule and within budget.

View Similiar Case Studies

In order to revitalize and meet stormwater codes, the abandoned parking area at the Shoppes at Fashion Square in Orlando, FL, required updates. With a permeable paving system and machine technology, we helped the client achieve their goals, save $1 million, and complete the project in just 10 days.

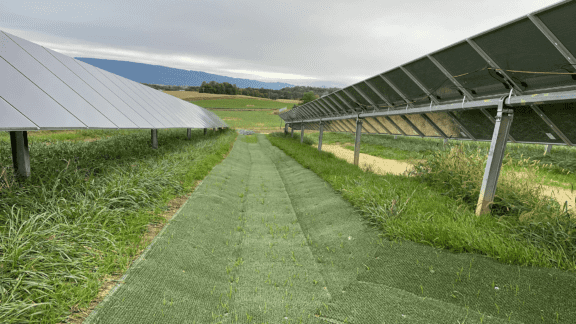

See how contractors mitigated erosion and sediment runoff at a solar farm in Roanoke Rapids, NC.

Learn how Ferguson Waterworks addressed some concerning erosion problems on a solar farm in Mt. Jackson, VA.