R-Tank Modules Meet HS25 Loading Requirements for Home Depot Parking Lot In NY

Discover how a cost-effective subsurface stormwater management system met HS25 loading requirements for a new home improvement store’s parking lot in Flushing, NY

Initial Concern

In Flushing, New York, a new home improvement store was being developed. With space constraints and a tight budget, it was important to select a reliable, cost-saving underground stormwater management system. Originally, the site was designed for a precast concrete system, however, the engineer preferred a shallow underground stormwater containment solution that could be installed beneath the future parking lot.

The Goal

Ultimately, the site engineer reached out to Ferguson Waterworks to provide a high void space, cost-effective, and shallow subsurface stormwater management system that meets HS25 loading requirements.

Solution

Originally, the underground stormwater system design required a large field of concrete leaching galleys. After reviewing pricing from contractors, the project team decided to revisit the design plans and evaluate other potential systems that would be more cost-effective and work better within the shallow cover conditions. R-Tank UD modules were chosen to replace the concrete leaching galleys as they would reduce the total depth of the system meanwhile maintaining the load-bearing capacity for heavy traffic loads commonly found in parking lots. Furthermore, this innovative stormwater chamber was cost-effective.

Ferguson Waterworks assisted in the redesign process. In addition, we provided preassembled modules and on-site assistance throughout the installation.

Installing the space-saving R-Tank Modules beneath the future parking lot.

Before the tanks were installed, the area was excavated and regraded. A smooth base layer of stone was then added and leveled to provide a suitable base to place the tanks. The R-Tank modules were positioned on a woven monofilament geotextile that covered the level stone base. Inspection ports were added and horizontal pipe connections were made while the tanks were being placed. The system was then sealed with woven monofilament geotextile. Once the system was sealed, a 12-in stone layer was added to encase it. This was followed by a layer of biaxial geogrid prior to the pavement being installed on the surface.

Results

Both the engineer and contractor were thrilled with the rapid installation of the system. The R-Tank Stormwater Modules offered both cost savings and installation efficiencies for this space-constrained parking lot.

View Similiar Case Studies

In order to revitalize and meet stormwater codes, the abandoned parking area at the Shoppes at Fashion Square in Orlando, FL, required updates. With a permeable paving system and machine technology, we helped the client achieve their goals, save $1 million, and complete the project in just 10 days.

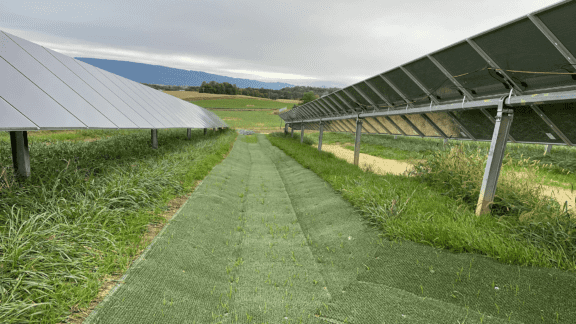

See how contractors mitigated erosion and sediment runoff at a solar farm in Roanoke Rapids, NC.

Learn how Ferguson Waterworks addressed some concerning erosion problems on a solar farm in Mt. Jackson, VA.