Scourlok Retention Wall in Hornell, NY

Find out how a cost-effective retention wall was quickly installed to protect an existing water main between two water tanks.

Initial Concern

A 0.83 MG water tank was being installed in close proximity to an existing tank, with the new tank at a lower elevation and a steep slope in between. Unfortunately, an existing water main located between the two tanks prevented the implementation of a reinforced slope. In order to maintain sufficient cover over the water main, it was decided that a retaining wall or vertical transition would be needed, and initially, a metal sheet pile wall was selected. Due to the cost and logistical challenges of the sheet pile, the design team decided to consider additional options. The project team settled on rock-filled gabion baskets for the wall, as a geogrid wall or anchor tie-backs were not feasible, but was also open to other cost-effective options.

Goal

Install a cost-effective retaining wall to achieve the required vertical grade differential while protecting the existing water main and water tank.

Installation & Solution

When the contractor approached Ferguson about gabion baskets, our team recommended using Scourlok instead, due to a much faster installation process. The contractor and engineer both approved of the idea and a 106 ft x 8 ft (at the highest point) Scourlok wall was selected. The Scourlok cells were shipped preassembled (prewrapped with geotextile on the inside and Pyramat on the outside) directly to the site and easily installed and connected following the pad’s radius. After each Scourlok segment was installed (approx. 15 ft long each), they were filled with on-site material, reducing the need to remove much of the material from the site or to import crushed stone/rock as fill. As an added benefit, the equipment required to install Scourlok was significantly smaller than corresponding equipment for sheet pile wall installation—a benefit that was especially notable in the jobsite’s tight quarters. Overall, the installation took 2 days versus the estimated 6 days that would have been required for the gabion wall.

Results

The Scourlok retaining wall turned out well and offered significant cost savings when compared to the proposed metal sheet pile or gabion wall. In addition, if the client desires to vegetate the wall in the future, they would have the option by filling the Pyramat pocket on the face of the system. As the site is industrial and not concerned with aesthetics, vegetation (while possible) was not a part of the installation process.

View Similiar Case Studies

In order to revitalize and meet stormwater codes, the abandoned parking area at the Shoppes at Fashion Square in Orlando, FL, required updates. With a permeable paving system and machine technology, we helped the client achieve their goals, save $1 million, and complete the project in just 10 days.

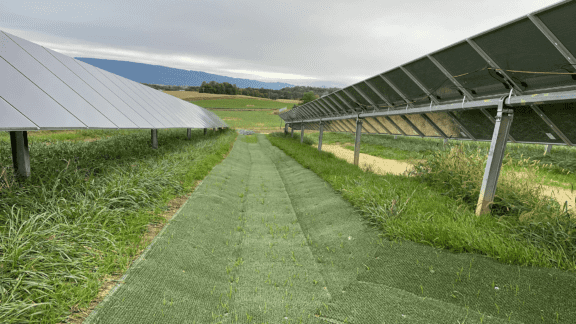

See how contractors mitigated erosion and sediment runoff at a solar farm in Roanoke Rapids, NC.

Learn how Ferguson Waterworks addressed some concerning erosion problems on a solar farm in Mt. Jackson, VA.