Mixed-Use Development Site Leans On Ferguson Waterworks for Green Stormwater Infrastructure

FocalPoint helps reduce traditional gray infrastructure, meanwhile accommodating stormwater BMPs and treating runoff before it enters the surrounding wetlands

Download Case Study

Project Background

A small group of local developers in Scarborough, Maine proposed the development of a 525-acre mixed-use site, The Downs. Their vision was to create a new “downtown” for the community. Like many other neighborhoods in the area, the character and feel of a town’s center had been lost due to rapid growth and urban sprawl. The developers of The Downs project worked to solve the housing shortage in Southern Maine, meanwhile enhancing the small-town feel. When Ferguson Waterworks was brought into the project, much of the development consisted of residential and commercial spaces, however, grocery stores, parks, recreational facilities, an innovation district, and more were in future plans.

Challenge

The mixed-use development site required green stormwater infrastructure to meet stormwater regulations and BMPs. The UGI solutions not only needed to accommodate a roadside installation but also to treat runoff in order to protect the surrounding wetlands.

Solution

The design engineer turned to FocalPoint Biofilters which handle high-flows within a small footprint. Furthermore, curb line pre-treatment devices were used to direct runoff to FocalPoint Biofilter beds. Then subsurface storage chambers, such as the R-Tank, detained the water.

Product Advantages

FocalPoint Biofiltration Systems are often combined with multiple stormwater solutions and BMPs for reliable, predictable, and cost-efficient treatment.

- Biofilters utilize a high-flow media which offers a conveyance rate of 100 inches per hr. This provides rapid treatment of runoff pollutants and reduces the size of traditional bioretention by 80%.

- With this system, developers benefit from a versatile footprint and design. For example, design mulch beds in accordance with landscaping plans and plant native vegetation that matches the natural aesthetic.

- Pair this system with Rain Guardians. These pre-treatment devices collect sediment and protect the FocalPoint.

- Cultec sub-surface chambers expand storage capacity and slow the discharge of treated stormwater

Project Scope

The Downs development project followed an aggressive construction schedule. Installation and work sequencing efficiency was a critical aspect to the success of the project. A project of this scale required multiple site contractors working on portions of the site simultaneously. The design engineer’s main requirement was to provide localized filtration and storage methods for stormwater runoff to this large-scale, newly developed land and to do so with space efficiency in mind.

Method

The design engineer utilized the FocalPoint Biofiltration System with subsurface chamber storage to treat and detain the stormwater runoff. The key advantage of the FocalPoint system is its high-flow filtration rate and small footprint which allow for design flexibility. A majority of the FocalPoints were designed within narrow esplanades along the roadway, providing localized filtration and thus preventing large-scale detention basins, which take up much-needed development space. The FocalPoint System is a functioning underground biofilter, but at the surface, the FocalPoint appears to be a natural-looking vegetated mulch bed that matches the landscaping plan set forth by the designers.

There were also wetlands surrounding the property that needed to be protected. Sixteen FocalPoints were used to reduce phosphorus and total suspended solids (TSS), allowing treatment of stormwater at the source. FocalPoints were the ideal solution as only 7′-wide areas were available, making traditional bioswales and raingardens unusable.

Why Ferguson Waterworks?

Ferguson Waterworks not only values high-quality products but also high-quality service. From start to finish, we provided product support for The Downs. This includes preliminary stormwater design assistance and installation guidance. FocalPoint systems offer design flexibility and effectiveness at treating runoff, rendering it a premium and adaptable stormwater solution.

View Similiar Case Studies

In order to revitalize and meet stormwater codes, the abandoned parking area at the Shoppes at Fashion Square in Orlando, FL, required updates. With a permeable paving system and machine technology, we helped the client achieve their goals, save $1 million, and complete the project in just 10 days.

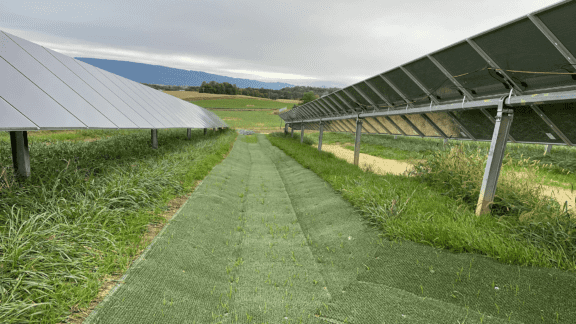

See how contractors mitigated erosion and sediment runoff at a solar farm in Roanoke Rapids, NC.

Learn how Ferguson Waterworks addressed some concerning erosion problems on a solar farm in Mt. Jackson, VA.